Handling Cold Chain Products: Temperature is the Key

Products with cold chain requirements are an important part in the inventory management of the pharmaceutical industry.

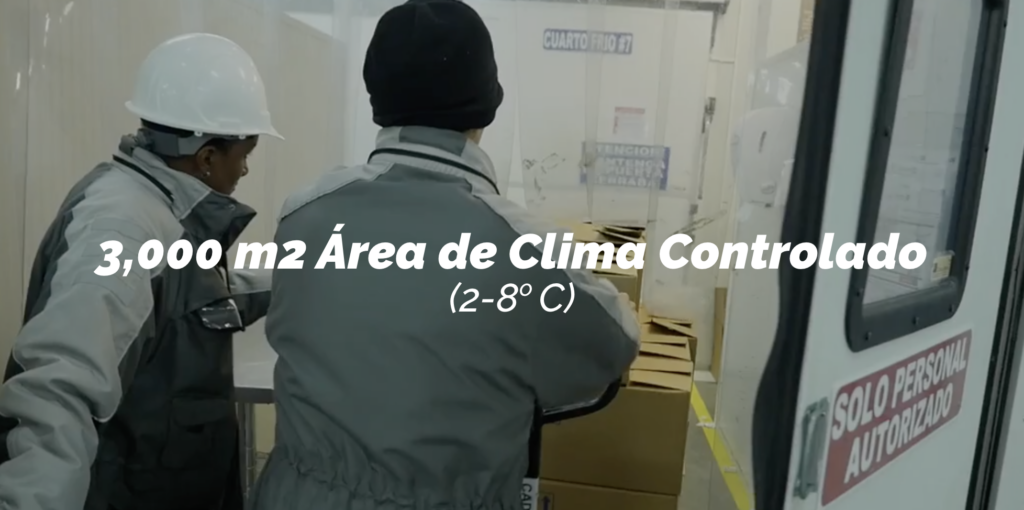

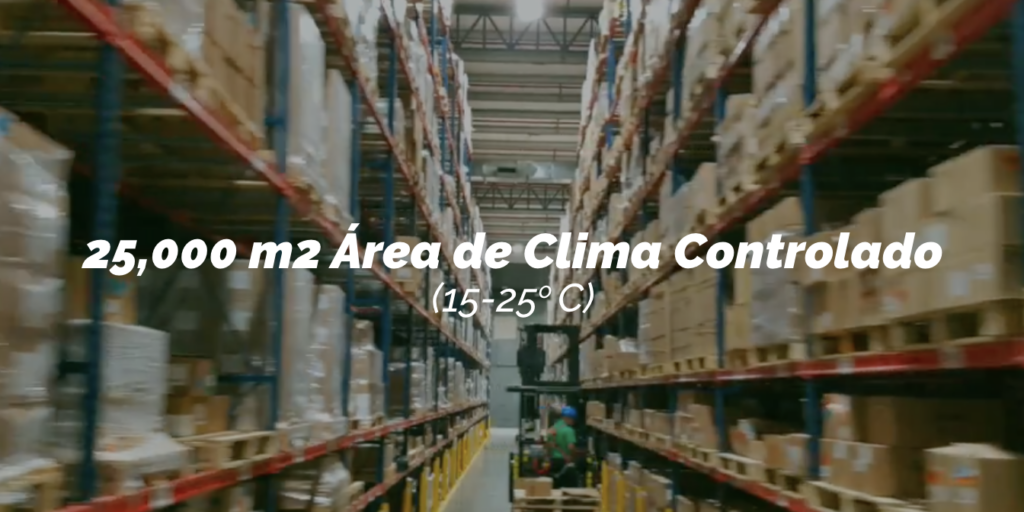

The biggest challenge will always be to keep the product within a temperature range according to the tolerance requirements that the composition of the product allows. Having validated facilities, with robust refrigeration systems, redundant capacity that allows contingency, and suitable personnel is key to functioning as a Distribution Center with the standards required by these products.

The main focus and the greatest challenge is on the products that require temperature between 2ºC – 8ºC during the entire storage and distribution cycle, the biggest challenge being shipments to destinations in Latin America where management is not consistent in each destination.

Just as a reference, about 60% of the problems that are registered in shipments of this type of product, have to do with breaks in the cold chain during transport.

The use of passive packaging has had a great evolution and is the solution that is being used to guarantee the cold chain during transit.

There are a number of variables that affect temperature control

- Size of the refrigerator to use to ship the product

- Configuration or arrangement of used cooling agents (gels)

These elements directly affect fluctuations in temperature inside the refrigerator, which can put at risk the integrity of the product.

Monitoring of the temperature during the storage and subsequent movement of the product in the different stages of the value chain, until finally arriving at the consumer, is fundamental .

It is for this reason that the monitoring of the temperature during the storage and subsequent movement of the product in the different stages of the value chain, until finally arriving at the consumer, is fundamental, since if the product is received with fluctuations, that is to say, it was exposed to temperatures above or below the range established for handling (2ºC- 8ºC), it is very likely that the product is no longer suitable for consumption and that the effect has been lost. If this is not handled correctly, apart from the economic impact, the lives of people could be included.

Hence, an important part of the link in the distribution chain is to have a supplier whose refrigerator guarantees the minimum risk of temperature fluctuation during its useful life, which is determined or established according to time, which is generally measured in days, from when the refrigerator is assembled, until it reaches the next stage of the process, which is usually a distributor in the country of destination.

Most refrigerators that are used today, are validated to ensure the temperature inside the package for 72 to 96 hours.

Because it is a requirement that has evolved and grown, it is important to stay ahead of the curve. A logistics operator specializing in the management of this type of product must have the experience and knowledge to ensure the cold chain, and in case of any mishap during its stretch of control, have contingency plans that involve, but They are not limited to:

- Redundant refrigeration equipment in the cold rooms, in case of failure of one device, enter to operate the other and thus maintain the temperature between 2ºC – 8ºC

- Product evacuation procedure, in case of redundant equipment failure

- 24/7 temperature monitoring in cold rooms

- Suitable personnel to certify cold rooms

This implies having a constantly trained and trained quality team that passes this knowledge to the operative team, which ensures having qualified personnel.

Conclusion:

A logistics operator that specializes in the handling of cold chain pharmaceutical products must have established the controls, processes, infrastructure and human equipment that guarantees to the final consumer, that the product has maintained the cold chain during the stages of reception, Storage, handling and transport of the product.

For pharmaceutical companies, having a strategic partner that has this type of specialization, gives you the confidence necessary for the proper marketing of medicines, with the minimum risk of product loss due to breakage of the cold chain.

J Cain & Co has been serving the pharmaceutical industry for more than 68 years as a regional distribution center from Panama to Latin America. We are proud to have the highest infrastructure riggers and a team of professionals committed to the quality and service that the cold chain requires.

BASC Certification

BASC – Business Alliance for Secure Commerce, is an international commercial alliance that pro

Panama, Hub of the Americas

Since before its own independence, Panama already had vital importance for international logistics a

Multi-country distribution center of 7 different business units

Industry: Technology Description: Our client, a manufacturer and marketer of technological products